- +86 173 1772 0909 (What’s App & Wechat)

- andy@strpack.com

A rotary pump filling machine is an essential piece of equipment for customers who need to accurately fill liquids with varying viscosities, such as sauces, pastes, and creams. For businesses in the food, cosmetics, and daily chemical industries, selecting the right rotary pump filling machine is an important factor in ensuring production efficiency, filling accuracy, and minimal product waste.

Many users rely on experience when choosing a rotary pump filler and consider the decision correct as long as the filling process runs smoothly without dripping or overfilling. However, as production scales up or industry regulations become more stringent, it becomes necessary to understand the differences between commonly used rotary pump filling machines and their characteristics in order to optimize filling performance and overall production efficiency.

Types of Rotary Pumps for Filling Machines

Rotary pumps work by trapping a fixed amount of liquid in a rotating chamber and transferring it to the discharge port. They are generally divided into several types, each suitable for specific filling applications:

Gear Pump Filling Machines

Overview:

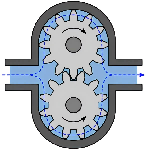

Gear pump filling machines use a positive displacement gear pump to deliver a stable and controllable flow rate. Due to their simple mechanical structure and continuous conveying principle, they are particularly suitable for medium to high viscosity liquid filling in industrial production lines.

Characteristics:

Simple structure with reliable and stable flow output

Suitable for medium to high viscosity liquids

Low shear force, minimizing product damage

Well suited for continuous and automated production lines.

Typical Applications:

Cooking oil filling lines, honey bottling machines, shampoo filling equipment, detergent filling systems, and various viscous liquid filling applications.

Key Advantage:

The key advantage of gear pump machines is that the pump structure and wetted parts can be manufactured using different materials. Based on this characteristic, gear pump filling machines can be designed either as standard models for non-corrosive liquids or as anti-corrosion models for aggressive chemical products.

The image shows a gear pump which used on our standard gear pump filling machine.

Standard Gear Pump Filling Machines

Description:

Standard gear pump filling machines are designed for non-corrosive liquids. Wetted parts are typically made of stainless steel or other conventional industrial materials.

Suitable Products:

Edible oils, syrups, honey, shampoos, conditioners, and general detergents.

Advantages:

Stable flow rate and good filling accuracy for medium to high viscosity liquids

Durable mechanical construction

Easy cleaning and routine maintenance

Cost-effective solution for common viscous liquid products

Limitations:

Not ideal for extremely low viscosity liquids. When filling very thin products, reflux may occur, reducing flow accuracy, and pulsation may appear at very low speeds. For liquids such as water or clear juice, gravity filling machines are generally a more appropriate choice.

Anti-Corrosion Gear Pump Filling Machines

Description:

Anti-corrosion gear pump filling machines are developed based on the same gear pump principle, with all liquid-contact parts made from corrosion-resistant materials such as PP, PTFE, PVDF, or special alloys, depending on the chemical properties of the product.

Suitable Products:

Bleach, acidic or alkaline solutions, disinfectants, toilet cleaners, and other corrosive liquid products.

Advantages:

Maintains the low shear force and stable flow characteristics of gear pumps

Excellent resistance to chemical corrosion

Suitable for continuous production of aggressive chemical liquids

Extended service life when handling acidic or alkaline products

Limitations:

Similar to standard models, anti-corrosion gear pump fillers are not recommended for extremely low viscosity liquids. For non-corrosive, low-viscosity products, anti-corrosive gravity filling systems remain a simpler and more economical option.

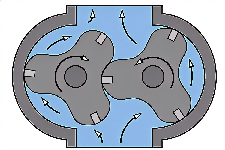

Lobe Rotary Pump Filling Machines

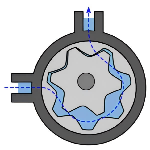

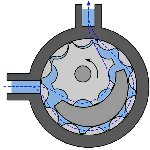

Characteristics: Gentle pumping action, capable of handling liquids with small solids, self-priming design for hassle-free operation.

Applications: Fruit puree filling lines, sauce bottling machines with particulates, dairy product filling equipment (yogurt, cream).

Advantages: High hygienic standards (meets FDA/CE requirements,with GMP-compliant hygienic design), minimal damage to fragile products—ideal for premium food filling.

The image shows a lobe pump which used on our rotory pump filling machine.

How to Choose A Suitable Pump Filling Machine for Your Production Line

The correct rotary pump filler depends on your product viscosity, required filling accuracy, and production speed—here’s a quick guide:

• Thin liquids (water, juice, chemical solutions):For thin liquids such as water or juice,a gravity filling machine or piston filling machine is a practical choice.

• Medium viscosity liquids (sauces, shampoos, detergents): Gear pump filling machines or lobe rotary pump filling machines work best for balanced efficiency and accuracy.

• High viscosity or particulate liquids (honey, fruit puree, creams): Lobe rotary pump filling machines provide gentler handling and better flow stability to preserve product quality.

Modern servo-controlled rotary pump filling machines allow you to precisely adjust the filling volume and speed. This ensures that each bottle or container receives the correct amount of product without overfilling or underfilling—completely according to your production line settings.

Understanding the type of rotary pump and its applications not only helps you choose the right filling machine but also improves production line efficiency, reduces product waste, and maintains consistent product quality across batches.

If you require further assistance, please feel free to contact us.

CONTINUE LENDO, MANTENHA-SE INFORMADO, SUBSCREVA E NOS CONVIDAMOS A DIZER-NOS O QUE PENSA DIGITE O SEU ENDEREÇO DE EMAIL